By Lorie Pella

From the very beginning Humber River Hospital’s redevelopment project was driven to be sustainable under the guiding design principles of Lean, Green and Digital When the new facility opened in October of 2015, it heralded a new era not just for the use of technology in North American hospitals – it also set a new standard for energy efficiency for comparable hospitals.

Using an integrated design approach for the energy-consuming systems across the new building, Humber set an aggressive target of achieving 50 per cent energy savings based on a model building with similar features.

The key indicator for measuring this is Energy Intensity, the total amount of energy used divided by the building area. Since opening, Humber River is leading the industry in this category. It is expected that the efficiency will improve by an additional 30 per cent as we continue to calibrate the new building systems.

In order to achieve this level of industry leading energy efficiency performance, Humber had to go beyond the traditional design and device selection, particularly because of the uniqueness of the new hospital having a 100 per cent fresh air supply – no recirculated air. We had to dig deeper.

We targeted the ‘waste’ heat emitted by people and equipment, recapturing it from the exhaust air before it leaves the building, and reusing it for preheating of water and new fresh air entering the building. This is done by forcing exhaust air through energy recovery wheels that spin slowly within the air handling units. The heat is captured and transferred back into the building systems.

One of our ‘Eureka’ moments came by discovering that, by slowing the air flow through the wheels enough, the efficiency of the heat wheels increased by 10 per cent, effectively making the 100 per cent outside air system cost-neutral. Facilities already pay to run equipment and keep occupants comfortable by running systems: the heat generated is the byproduct of the day-to-day operations – it only makes sense to reuse it to reduce consumption and operating costs. The use of waste heat also allowed the hospital to install snow melting capability within the sidewalks at main entrances, helping prevent slips and falls for little to no cost beyond the minimal initial capital cost.

Our HVAC (heating ventilation air conditioning) design is geared to reduce the fan power required to move air through the building – at 1.8M square feet it’s a lot of air to move. The combination of oversizing the ductwork, slowing down the air flow and the use of secondary fans leads to a significant drop in electricity to power the fans. This is important because there is an exponential drop in electricity use when fan motor speeds are lowered. When fan operations are coordinated so off-hours use is reduced, a domino effect is created, further enhancing utility reductions since less heating, cooling and humidification are required during those times.

Lighting design uses digital technology and intelligent controls: occupancy sensors; off-hours lighting level controls where it makes sense (e.g. some clinics); motion sensitive lighting; daylight harvesting; all controlled centrally to minimize electricity use (and costs) while using schedules that suit the building’s occupancy needs. LED lighting and high efficiency fixtures are used throughout and have digital ballasts to allow building operators to adjust and set each light fixture correctly. The system also pushes data back to building operations so performance indicators can be reviewed and further adjustments made.

Humber River employs a leading-edge window tinting system in our inpatient rooms: VIEW dynamic glass. Each pane has a nano-thin coating that tints when a direct electrical current (DC) is applied to it. Each piece of glass has its own controller with an IP address traced back to the central server, where algorithms allow optimized daylighting and comfort by tinting windows according to on-demand patient control overrides from the bedside terminal. Unoccupied rooms are automatically controlled using daylight sensors and preset scheduling.

This improves efficiency by controlling the amount of sunlight penetration to suit the season by leveraging the heat gain in winter and heat reduction in summer, mitigating heating and air conditioning needs. In many ways this is similar to occupancy controls for lighting. Outdoor views are never blocked while privacy is always maintained based on the tint level.

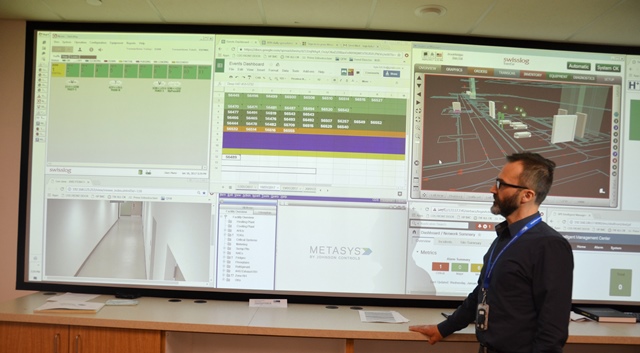

These and other energy efficiency systems are all tied into the building’s operations centre, where they are viewed on a dashboard monitored 24/7 by the facility operators.

This high level of integration across the physical plant, the result of a rigourous focus on Green as a primary principle for the design and operations of the new Humber River Hospital, has achieved industry-leading performance, setting new benchmarks for hospital design across North America.

Lorie Pella, P.Eng. is Director of Planning at Humber River Hospital.